Key Points

- Project Approved: Pinal County Planning Commission unanimously approved Project Bella, a 480MW natural gas and 440MW battery storage facility on 351.8 acres near Casa Grande.

- Energy Operations: The natural gas component operates as a “peaker plant” that will only run when grid demand exceeds capacity, with batteries storing excess grid energy during low-demand periods and redeploying it when demand is higher.

- Strategic Location: The site leverages existing infrastructure including a 500kV transmission line, 230kV line, and natural gas pipeline already on the property, requiring no additional public infrastructure.

- Community Benefits: Project commits $4.1 million over 10 years for a community foundation providing grants to residents within one mile, plus $1.35 million for fire equipment and land for a fire station.

- Environmental Impact: The facility will use significantly less water than current agricultural operations (205-320 acre-feet vs. 466 acre-feet annually) and includes extensive sound mitigation measures.

- Economic Impact: The project will generate an estimated $167 million in tax revenue over 25 years and employ 14 full-time workers with salaries ranging from $60,000-$175,000 annually.

- Next Steps: The applications advance to the Pinal County Board of Supervisors for final approval, with construction planned for 2027 and operation by Spring 2028.

Commission Unanimously Backs Natural Gas and Battery Storage Project Near Casa Grande

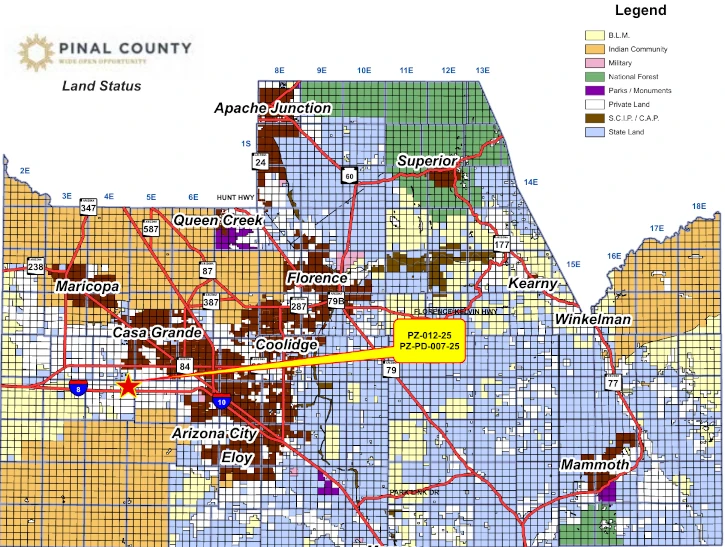

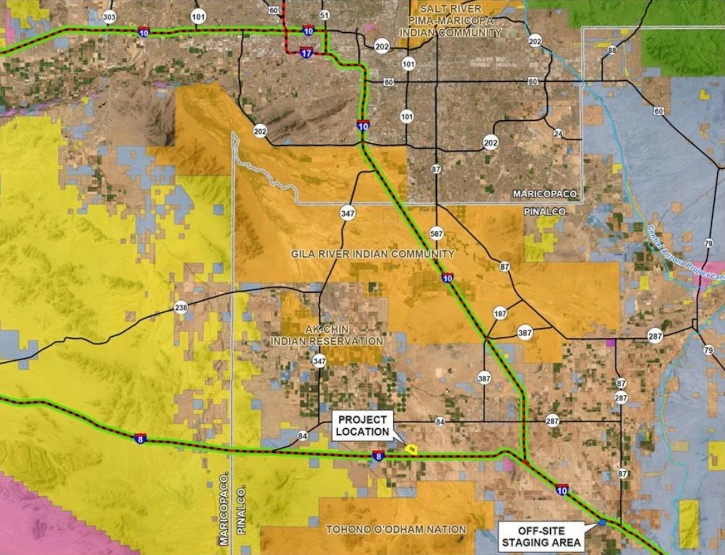

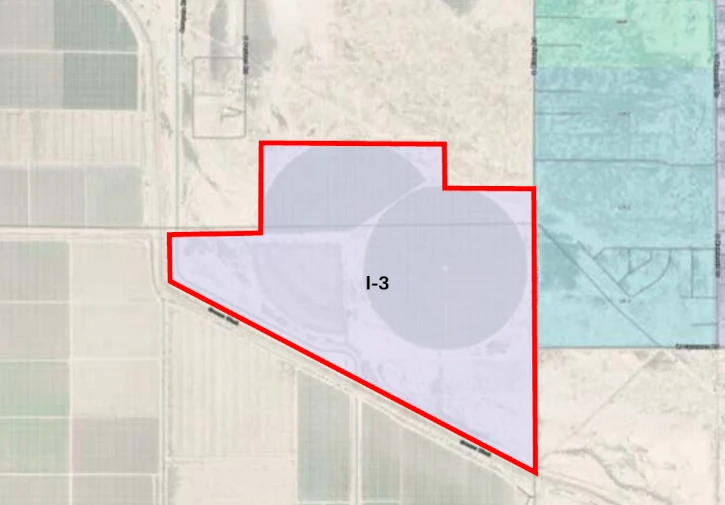

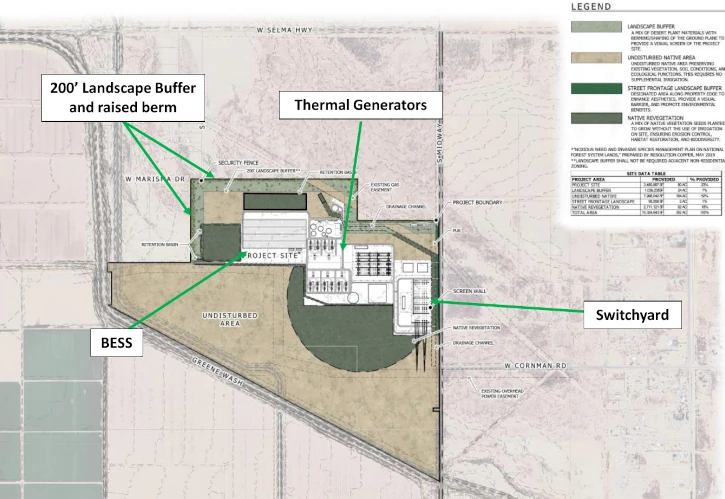

The Pinal County Planning and Zoning Commission unanimously approved two key applications for Project Bella, a proposed 480-megawatt natural gas power generation and 440-megawatt battery storage facility, during their July 7, 2025 meeting. The commission voted 7-0 to approve the rezoning from General Rural to Industrial I-3 with one stipulation and the Planned Area Development overlay with 12 stipulations for the 351.8-acre site located south of Selma Highway and north of Interstate 8.

Project Overview and Energy Market Need

Developer Alex Hayes of Withey Morris Baugh, representing Seguro Energy Partners, told commissioners the facility addresses Arizona’s growing energy demands as the state reaches capacity limits of existing energy infrastructure.

Hayes explained the project would provide resource adequacy and help maintain reliable power for the state, noting “we need to bring new generation sources and new capacity sources online.”

The facility consists of two main components: Cazador del Sol, featuring ten GE LM6000 natural gas turbines with 480 MW capacity, and Atrapa Soles, a 440 MW battery energy storage system. Hayes noted the generation component “is what’s considered a peaker plant” that differs from combined cycle plants that run continuously. “These turbines will only be used when demand on the grid exceeds what’s the capacity on the grid,” he explained.

Energy Operations and Grid Integration

The project employs three key operational concepts: frequency regulation through quick dispatch technology, peak shaving to provide reliable capacity during periods of highest electricity demand, and load shifting to manage electricity demand efficiently.

“The battery storage will store power during the day when that solar generation is cheap and abundant, and then redeploy that when the demand is higher,” Hayes explained. “This is called load shifting. It helps integrate renewables better.”

Commissioner Tom Scott sought clarification about battery charging sources. “I assume it’s not coming from your gas-powered plant, right?” Scott asked.

“No,” Hayes confirmed. The batteries pull power directly from the grid rather than from the facility’s natural gas turbines.

Strategic Location and Infrastructure

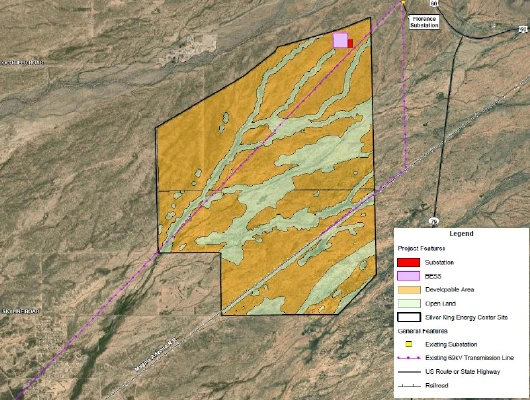

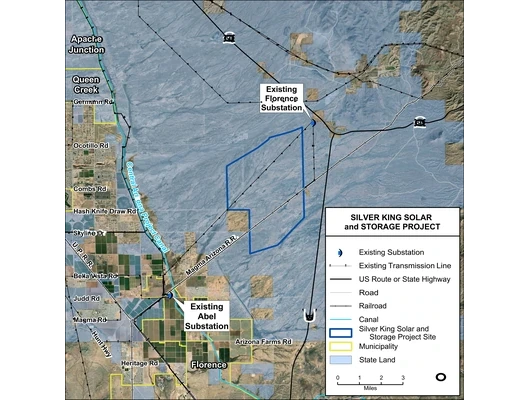

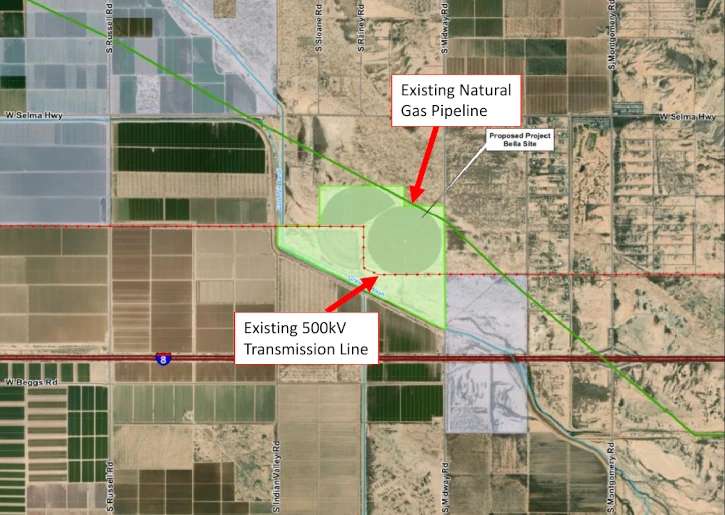

The site’s location capitalizes on existing infrastructure already in place that makes it uniquely suited for power generation. The Duke/Pinal Central 500kV transmission line currently runs through the property, along with WAPA’s Test Track to ED-5 230kV transmission line and an El Paso Natural Gas pipeline that have established easements on the site.

“All the gas provided for the thermal generation will come from that gas line, and all the interconnection will occur on site,” Hayes noted. “So there’s no need for additional infrastructure and no need to encumber additional land with new transmission lines.”

Power Distribution and Utility Partnerships

Hayes confirmed the facility has advanced negotiations with Electrical District 4 and Salt River Project (SRP) for power purchase agreements. When Commissioner Bryan Hartman asked about the progress of these negotiations, Hayes responded they were “very close.”

Commissioner Scott expressed concern about power leaving the county. “It’d be a shame for this thing to get going and then ship all the electricity out of this county,” Scott observed.

Hayes assured commissioners that “the utilities that we’re negotiating serve Pinal County, and there are some particular projects that would very likely directly benefit from this project.”

Land Use Efficiency Comparison

Hayes highlighted the project’s land efficiency compared to solar installations. The facility requires 150 acres of development within the 351.8-acre site, with the remaining land preserved as undisturbed open space or landscaped buffers. A solar project with similar capacity would require “at least 10 times the amount of land.”

“It’s a very land efficient use,” Hayes emphasized.

Site Description and Surroundings

The property currently serves agricultural purposes and sits in a sparsely populated rural area. The nearest residences lie over 4,000 feet from the generators to the east, with only four or five homes about 2,000 feet away to the northwest. Staff planner Valentyn Panchenko noted the property has “undeveloped GR-zoned land to the north and west” with “GR residential properties to the northwest.”

Sound and Visual Mitigation Measures

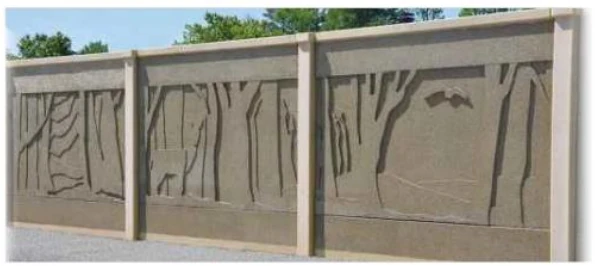

Project Bella incorporates extensive sound and visual screening measures. The facility includes a 200-foot landscape buffer along the northern and western boundaries adjacent to residential zoning, featuring earthen berms and native desert plantings. A seven-foot precast concrete sound wall will run along Midway Road frontage.

“All core equipment—such as gas turbines, transformers, and battery energy storage systems—centrally within the site,” creating “significant physical separation from surrounding properties, with no major noise-generating equipment located closer than approximately 430 feet to the nearest property line.”

The 60-foot generator stacks will be less than half the height of the existing 140-foot transmission towers on the property.

Sound Studies and Monitoring

SWCA Environmental Consultants conducted sound modeling showing only a 1.5 dBA increase above the existing 42.8 dBA baseline—well below the 60 dBA daytime and 55 dBA nighttime thresholds set by Pinal County. Hayes noted this increase is “barely perceptible to the human ear.”

A follow-up study will be conducted within 120 days of commercial operation, and if results exceed ordinance limits, additional mitigation will be implemented as required by the PAD. When Commissioner Karen Mooney asked what those measures might include, Hayes mentioned “sound baffling” and “different kind of engineering solutions that would be part of the actual structure itself to mitigate the sound.”

Water Usage Comparison

The project will use significantly less water than current agricultural operations on the site. Hayes reported current agricultural use averages 466 acre-feet annually, while Project Bella projects using between 205 and 320 acre-feet, with a maximum of 420 acre-feet over a three-year average.

“This project will use less water than is currently used on the site with the agricultural operations,” Hayes emphasized.

Air Quality and Environmental Concerns

The facility received air permits from both Pinal County Air Quality Control District and EPA review. According to Hayes’s presentation, the equipment includes “selective catalytic reduction (SCR) and oxidation catalyst technology for the control of NOx, VOC, and CO emissions” with “continuous emissions monitoring equipment for monthly reporting, and ongoing compliance verification.”

Hayes compared the turbines to existing facilities: “It’s the same equipment that’s used at Sundance, which is run by APS, and Coolidge, which is run by SRP.”

Regarding the Sundance facility, documents show the Sierra Club filed a petition in June 2024 claiming the facility’s permit “failed to include practically enforceable limits on PM₂.₅ emissions” and lacked “recurring stack testing” for long-term compliance. The EPA denied the petition in November 2024, finding that Pinal County had “amended the permit to require recurring PM₁₀ stack testing every 5 years” and that “PM₂.₅ emissions are calculated based on PM₁₀ measurements.”

Fire Safety and Battery Technology

There have been major BESS fires recently that has prompted concern from the commissioners:

| Date | Location & Capacity | Summary |

|---|---|---|

| Jul 30, 2021 | Moorabool, Australia – 300 MW / 450 MWh | Fire during commissioning; coolant leak led to electrical arcing and thermal runaway in a Tesla Megapack. Burned ~6 hrs, site monitored afterward. Read more |

| Sep 4, 2021 | Moss Landing Phase I, CA – 300 MW / 1,200 MWh | Smoke from a failed bearing in an air‑handling unit triggered water suppression, damaging battery modules via short circuits. No flames; shutdown followed. Read more |

| Feb 13, 2022 | Moss Landing Phase II, CA – 400 MW / 1,600 MWh | Overheating caused by water entering through vent shields led one Megapack to burn for about 6 hrs. Over 80 units were taken offline. Read more |

| Apr 18, 2022 | Chandler, AZ – 10 MW (Salt River Project) | A smoldering fire occurred in a battery storage container. No injuries; firefighting robots and hazmat crews responded. Read more |

| May 15, 2024 | Otay Mesa (Gateway), CA – 250 MW / 250 MWh (1‑hr) | Fire at LS Power’s Gateway BESS reignited several times over two weeks. Evacuations were issued; EPA led cleanup efforts. Read more |

| Jan 16, 2025 | Moss Landing Phase I, CA – 300 MW / 1,200 MWh | Major fire destroyed ~80% of batteries in the building. About 1,200-1,500 residents evacuated; fire burned for days before burning itself out. Read more |

Fire safety expert Brian Scholl of Energy Safety Response Group addressed commissioners’ concerns about battery fires. Scholl, a retired 23-year Phoenix Fire veteran, explained modern battery technology differs significantly from earlier systems.

“A lot of what you’re talking about is the first generation battery. They’re called nickel, manganese, cobalt. Very heavy metals, very toxic fumes that came off those fires,” Scholl said. “We’ve come a long way and now they’re called LFP, or lithium iron phosphate batteries. A lot more tolerant and don’t have the toxic fumes that we see.”

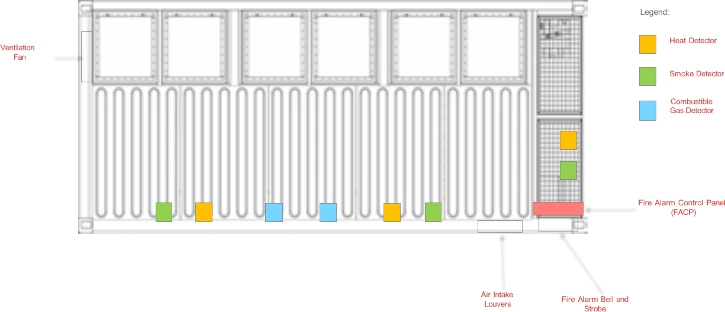

The Atrapa Soles battery system will use SolBank 3.0 lithium iron phosphate (LFP) technology, which complies with NFPA 855 and UL9540A safety standards. The system includes active explosion prevention, battery management systems with gas detection, and engineered fire propagation barriers designed to contain thermal runaway events within individual battery modules.

Commissioner Mooney asked about toxic chemicals during battery thermal runaway. Scholl responded: “All our testing that we do and across the country in different testing labs, all the smoke that comes off these in thermal runaway are the same smoke that comes off a commercial fire, or even a residential fire.”

Regarding recent incidents, Scholl addressed concerns about lithium contamination: “I read that there was some other things. But that’s because it was an old coal plant too. And it was in a building not designed for what it was doing. And plus, it was first generation batteries. Nickel, manganese, cobalt. So, a lot of bad things in those batteries. And not the batteries that are gonna be here.”

When Commissioner Scott asked about containment, Scholl confirmed: “There will be potentially some off-gassing, but the fire itself stays to that enclosure, and that’s what we’ve tested and we can prove that.”

Community Foundation and Working Group

Project Bella commits $4.1 million over 10 years to establish a Community Foundation providing grants to residents within one mile of the facility. Hayes explained the foundation would be administered by an established community foundation, noting they are “currently working with the Arizona Community Foundation” and “also in discussions with Maricopa Community Foundation.”

Eligible projects include “energy efficiency, replacing windows, looking at their wells” and other community improvements. Commissioner Scott asked about grant types, and Hayes clarified they would establish criteria for “things like maybe replacing windows for energy efficiency, well testing, new landscaping.”

When Vice-Chairman Robert Klob asked about continuation beyond 10 years, Hayes clarified that while funding commits to 10 years, “there will be a community liaison and a point of contact for the community on an ongoing basis for this project.”

Fire Station and Emergency Services

The project will donate land and equipment for a fire station to serve the currently unprotected area. Hayes explained: “There is no fire jurisdiction that covers this property. I think the residents in the area, their current plan is if their house lights on fire that it’s just to let it burn.”

Project Bella will provide fire equipment and land for a fire station, and will “contribute a lot of upfront costs to stand up that fire and medical authority.” According to presentation materials, the fire equipment procurement cost is estimated at $1,350,000. The project will also fund “additional EMS equipment” for community benefit.

Commissioner Scott asked about funding sources. Hayes responded: “Project Bella would be donating the land and some equipment. We’re probably building the structure that exists on that property, but then we’d be partnering with that Pinal County Fire Medical Authority for their ongoing operations.”

Economic Impact and Staffing

The project will generate an estimated $167 million in new tax revenue over a twenty-five year period, averaging $6.7 million annually compared to current agricultural use generating about $4,500 annually.

The facility will employ 14 full-time workers with high wages totaling $2.2 million in annual payroll. Positions include a plant manager earning $175,000, various engineers earning $130,000-$145,000, and operations technicians earning $95,000-$105,000.

Construction will create “hundreds of jobs if not in the thousands” during the building phase. Hayes provided the following table to estimate full time employment expectations.

| Position | Positions | Initial Salary | Total with Loading (w Taxes & Benefits) |

|---|---|---|---|

| Plant Manager | 1 | $175,000.00 | $250,250.00 |

| Admin Assistant | 1 | $60,000.00 | $85,800.00 |

| Electrical/Controls Engineer | 1 | $145,000.00 | $207,350.00 |

| Mechanical Engineer | 1 | $140,000.00 | $200,200.00 |

| Compliance Engineer | 1 | $130,000.00 | $185,900.00 |

| O&M Supervisor | 1 | $120,000.00 | $171,600.00 |

| O&M Tech/operator | 6 | $95,000.00 | $815,100.00 |

| O&M tech/I&C | 2 | $105,000.00 | $300,300.00 |

| Total | 14 | $2,216,500.00 |

Renewable Energy Capacity Discussion

Vice-Chairman Klob raised concerns about renewable energy effectiveness, citing recent studies suggesting alternative energy sources provide “such a small percentage of what is actually needed that it’s almost like not doing anything at all.”

Hayes responded: “Until we have viable nuclear generation, then natural gas generation is about the least land-intensive generation source we can have. So you compare a project like this, again, it’s about 150 acres, compare that to a solar project that has a similar capacity, you’re looking at thousands of acres.”

He added: “I look forward to the day when we can figure out how to do modular nuclear.”

Klob laughed and noted: “I think we approved it a couple years ago to allow it in the county.”

Public Support

Several union representatives spoke in favor of the project. Gary White of the United Brotherhood of Carpenters noted: “I’ve never seen this in all my years of doing this, a company go so far for the community.”

Richard Garcia of Operating Engineers Local 12 emphasized the project would “produce hundreds of good-paying construction jobs with good benefits.”

Cezar Corral of Boilermakers Local 627 called it “real jobs for local workers, real investments in our communities, and real progress for Arizona’s economy.”

Community Engagement

According to citizen participation summaries, approximately nine neighbors attended the May 27, 2025 meeting. Feedback was mixed but largely constructive, with some attendees expressing desire to preserve rural character while others understood and appreciated the project’s intent and its alignment with existing infrastructure.

No formal opposition emerged during the meeting, and staff reported receiving no opposition letters from the public.

Project Timeline

Pending approvals, construction will commence in 2027 with commercial operation planned for late 2027 to Spring 2028.

The applications now advance to the Pinal County Board of Supervisors for final approval, where the commission’s unanimous recommendation will carry significant weight in the decision process.